1. Overview

What is Sodium Carbonate?

Sodium Carbonate, also known as soda ash or washing soda, is a chemical compound with the formula Na2CO3. It is a white, water-soluble salt that is commonly used in a variety of industrial and household applications. Sodium Carbonate is produced by the Solvay process or extracted from natural sources like trona ore.

In industry, Sodium Carbonate is used as a key ingredient in the manufacturing of glass, where it acts as a flux to lower the melting temperature of silica. It is also employed in the production of detergents, where it helps to remove grease and oil stains. Additionally, Sodium Carbonate is used in water softening, chemical synthesis, and as a pH regulator in various processes.

What material is compatible with Sodium Carbonate?

1.5SG with hexene PE

2. Chemical Dosing Solutions

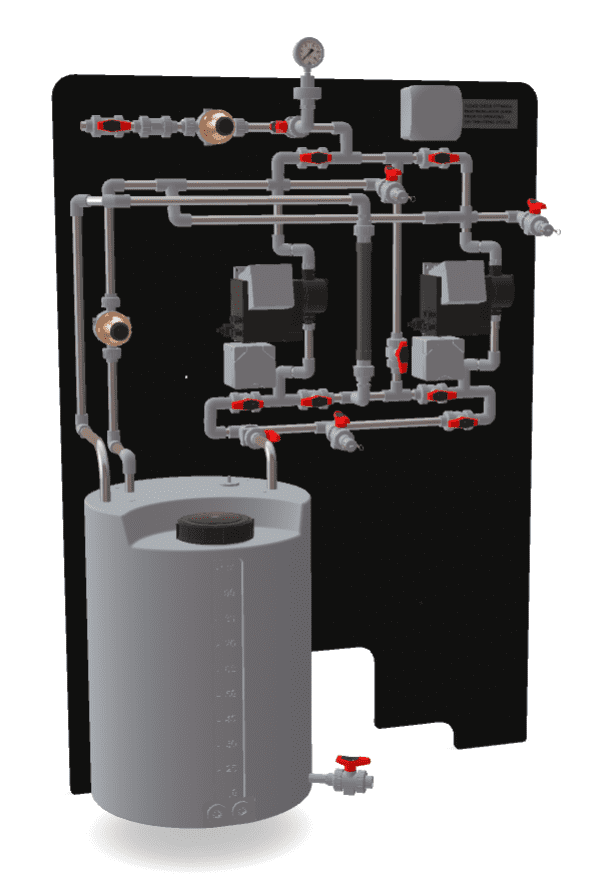

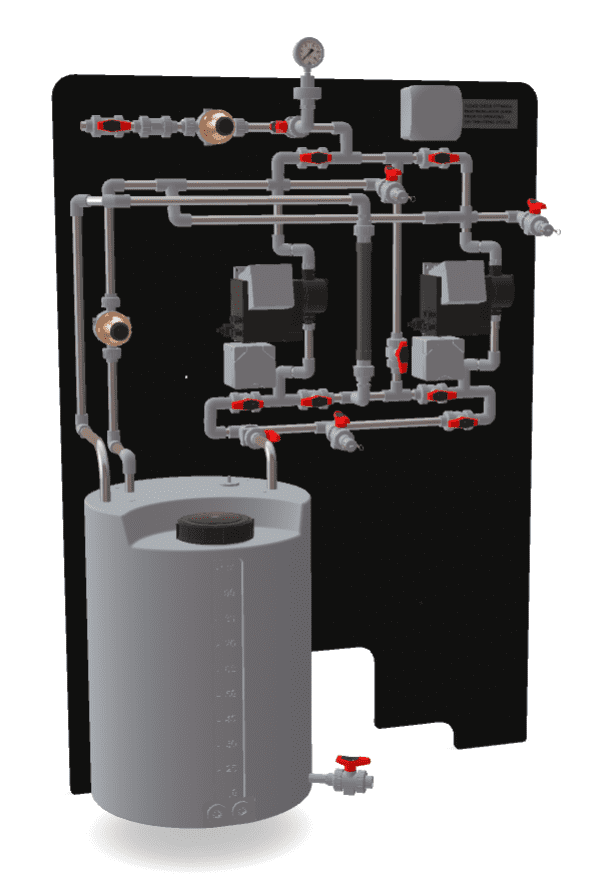

Pre-engineered Dosing Systems

Our pre-engineered dosing systems are designed for precise and efficient dosing of Sodium Carbonate. These systems are pre-engineered to offer a dosing range which is off-the-shelf and suitable across a wide range of industries. To configure a pre-engineered dosing system suitable for your application, this range offers:

Key Features:

Pump Arrangements: Duty or Duty/Standby pump arrangements.

Pump Options: 7.5 LPH @ 16 bar up to 200 LPH @ 4 bar – Grundfos DDA Dosing Pumps.

Pipework and Valves: +GF+ sch80 pipework and valves.

Cables and Junction Box: Control Cables and Junction Box.

Mounting: These dosing systems are typically mounted inside the Double Door Cabinet and can be integrated to the side of a storage tank or standalone.

Documentation: Detailed drawings, datasheets and step files available for these systems.

Custom dosing systems

Our custom dosing systems are tailored to meet the unique requirements of your specific applications. Polymaster builds custom dosing systems to match client-supplied P&ID’s and we follow the end-users’ specifications, such as a Water Utilities technical specification.

Key Features:

Customised Systems: Systems built to your specifications.

Precision Dosing: Advanced pumps and controls for accurate chemical delivery.

Integration: Seamless integration with your current processes and systems.

Safety and Compliance: Designed to meet all relevant standards and end-user specifications.

Large Systems: We can build large systems for large-scale applications.

3. Chemical Storage Solutions

Tanks for Sodium Carbonate Storage

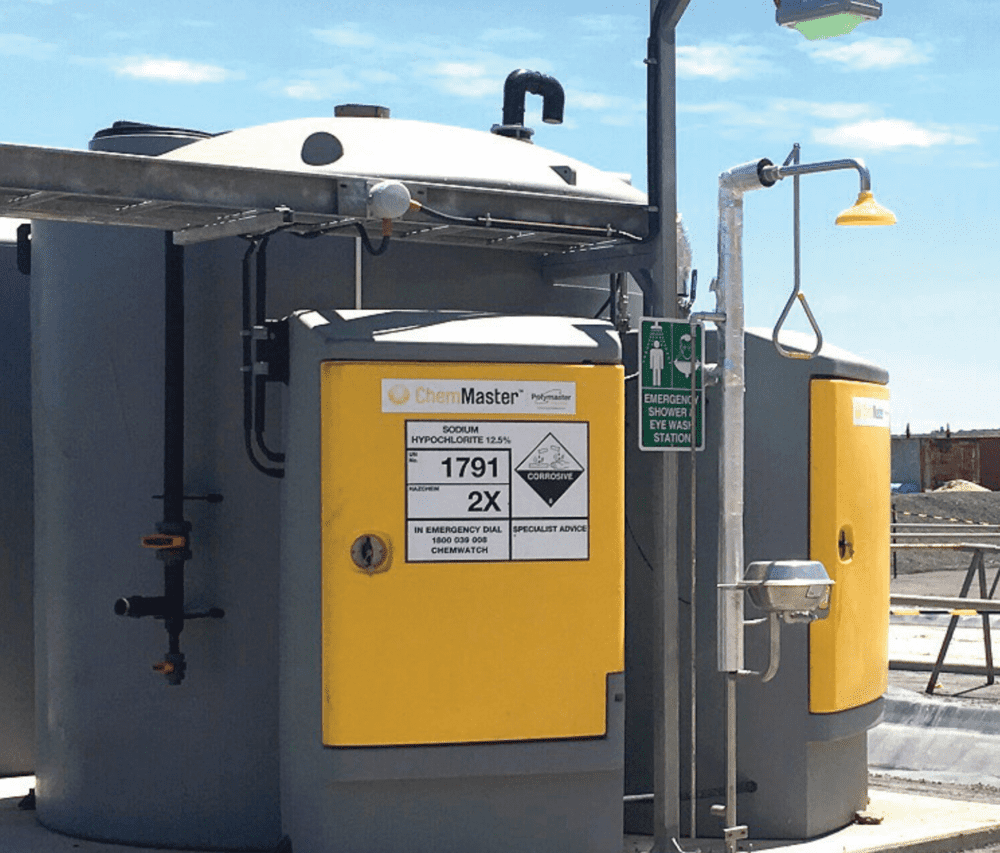

Polymaster’s Self-Bunded range is the ultimate storage solution for Sodium Carbonate. This range incorporates the bund with the storage tank, providing a bund capacity of 110% of the internal storage tank. In the unlikely event of a leak, this design prevents chemicals from coming into contact with the environment and personnel. Polymaster’s chemical tanks are not rainwater tanks and follow strict QA processes, such as hydro testing each tank to ensure they are 100% leak-proof.

CDU 110L/220L

Small chemical storage tanks offer advantages over large storage tanks in terms of flexibility, accessibility, and safety. Their smaller size allows for easier handling and transportation, making them ideal for labs, small-scale industrial operations, and fieldwork where mobility is key.

These tanks are suitable for environments with limited space, allowing convenient storage in confined areas. They also facilitate precise inventory management, reducing the risk of overstocking and chemical waste. They can be easily replaced or cleaned, ensuring better hygiene and reducing cross-contamination.

IBC Storage (1,000L)

Intermediate Bulk Containers (IBCs) are versatile and widely used due to their large capacity and convenient design.

Polymaster’s unique Enclosed IBC Bund solves many of the problems associated with IBC storage and chemical/fluid decanting in a weather-resistant, purpose-built enclosure.

Constructed from high-grade polyethylene, the Polymaster Enclosed IBC Bund allows for easy forklift movement of IBCs in/out, with a simple connection made to a 250 litre day tank, eliminating OH&S issues associated with IBC handling.

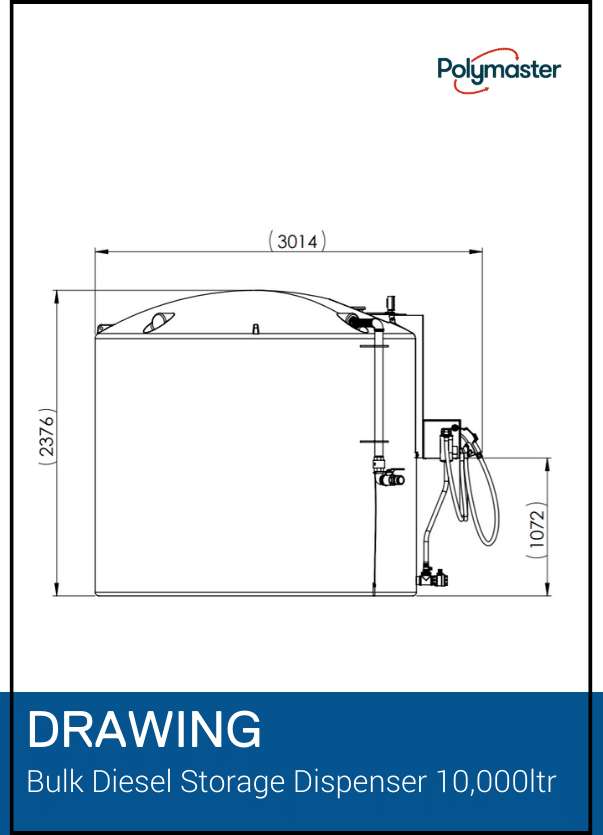

Bulk (1,500L - 30,000L)

Large chemical storage tanks offer significant benefits over small tanks in terms of efficiency, cost-effectiveness, and operational capacity. These tanks store substantial volumes of chemicals, reducing the need for frequent refilling and minimising downtime in industrial processes. This efficiency translates to lower storage costs and the ability to purchase chemicals in bulk at discounted rates.

Large tanks also centralise storage, simplifying inventory management and logistics while ensuring a continuous supply of necessary chemicals. Fewer large containers reduce the risk of leaks and spills, and these tanks are equipped with advanced safety features to handle hazardous materials securely.

Accessories for Sodium Carbonate Storage

Accessories give you the ability to decanter, store, mix and dispense with ease. We ensure you have a safe and effective solution for storing and dosing aggressive chemicals.

Dosing Skids

Polymaster provides dosing pipework and skids that assist in controlling the flow rate of Sodium Carbonate used in various treatment setups. These systems ensure precise and efficient chemical dosing.

Chemical Filling Stations

Polymaster’s chemical filling stations offer a safe and efficient solution for unloading Sodium Carbonate. Designed for ease of use, these panels ensure secure and controlled chemical transfer.

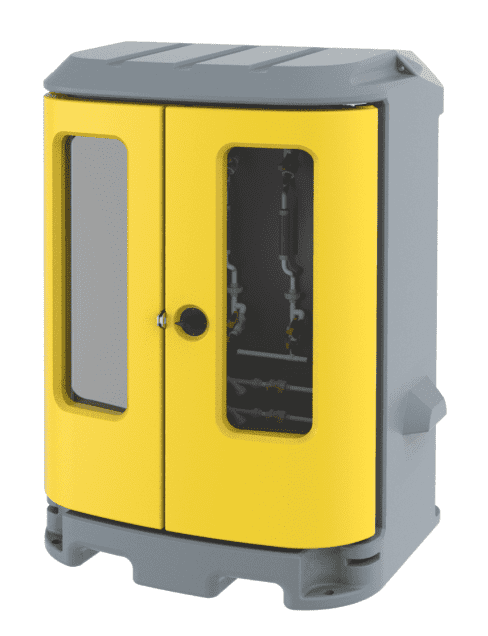

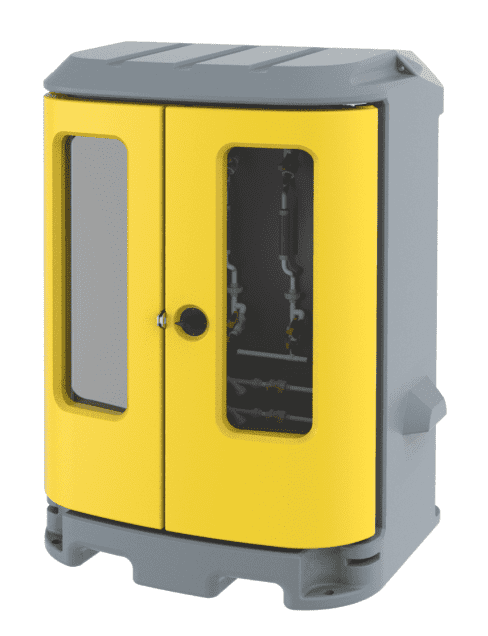

Cabinets

Chemical Dosing Systems – made easy at Polymaster for all applications, with flexible dosing options available ranging from a standalone cabinet to a complete package. These cabinets ensure safe and organised storage of Sodium Carbonate dosing equipment.

4. Case Studies

Upgrading the Dungong Wastewater Treatment Plant

Find out how Polymaster was involved in the completion of a $28 million upgrade project to improve Dungong’s water quality.

5. Applications

What are the applications for Sodium Carbonate?

Sodium Carbonate is a versatile chemical with a wide range of applications across various industries.

Here are some of its primary uses:

Water Softening

Sodium Carbonate is used in water treatment processes to soften water by removing calcium and magnesium ions. This prevents the buildup of scale in pipes and boilers and improves the efficiency of detergents in laundry applications.

Chemical Synthesis

Sodium Carbonate is used as an intermediate in various chemical synthesis processes. It is involved in the production of sodium compounds such as sodium bicarbonate (baking soda), sodium silicate, and others. It also serves as a pH regulator in many chemical reactions.

6. FAQ

Sodium Carbonate is a common food and beverage additive, but by itself it is a highly irritating substance that is toxic to inhale. It is also corrosive when mixed with water. It is important that it is stored within a container that is resistant to corrosive chemicals. This means within a tank or container that is built for the purpose of holding aggressive chemicals. It is very important to store sodium metabisulphite in a well-ventilated environment.

Store Sodium Carbonate in a cool, dry, and well-ventilated area away from direct sunlight. It should not be stored above 24°C.

Use containers made of compatible materials, such as our 7032 grade hexene 1.5SG to store Sodium Carbonate.

Store Sodium Carbonate separately from other chemicals, particularly bases, which can react with it and cause dangerous reactions.

Ensure that Sodium Carbonate containers are tightly sealed and labelled with the proper hazard warnings.

Regularly inspect and check your tank for any signs of damage or wear that may occur and get them repaired immediately.

When it comes to storing Sodium Carbonate, what you are storing it with is just as important as you can cause serious harm to people on-site or the environment around you. Sodium Carbonate should not be stored with bases or any other chemicals that can react with it.

When it comes to the storage and handling of sodium carbonate it is important that it is handled safely, and that everyone on-site is kept safe. Here are a few guidelines to follow to keep your workplace safe:

Store the chemical in its own designated area, away from other chemicals and direct sunlight.

If Sodium Carbonate is exposed to direct sunlight and heats up, it can produce irritating, poisonous and/or corrosive gases.

With any type of corrosive chemical using the appropriate personal protective equipment (PPE) such as gloves, goggles and face shield is a must, Sodium Carbonate is no different.

Avoid inhaling Sodium Carbonate fumes or mist, which can cause respiratory irritation and other health problems.

Always handle Sodium Carbonate with care and avoid splashing or spilling it.

7. Resources

This Chemical Compatibility Chart provides a comparison of the chemical resistance of our Specialty Grades of Linear Low Density Polyethylene, High Density Polyethylene and Polypropylene Polymers in different chemical environments.

Download The Chart

We also have additional resources available on all our chemical tanks, dosing skids and accessories such as:

- GA/PDF drawings for all tanks.

- Step files to easily incorporate into your CAD files.

- Datasheets on each tank, including different SG and Chemical Grade materials.

Make An Enquiry