Highest Quality & Standards

Find your local distributor store

Polymaster’s poly rainwater tanks are manufactured and distributed across Victoria, South Australia, and Southern New South Wales. Whatever your property’s size, locale and annual rainfall, we’ve got the right poly water tank for your needs and budget.

What Our Clients Say

I am proud to supply this feedback as it has been a long time since I was treated so amazingly well as a customer until I dealt with Polymaster. A) received excellent Pre Sales & Service from your dealer, Martha at Electel. B) Then 10 days before delivery I received a positive call from a polite young lady who ran through the complete scope of the order. To say I was appreciative was an understatement. Wished more companies had your service commitment / DNA. C) Then a day before delivery I received a polite phone call from a truck driver who introduced himself as your driver and ran through the logistics / offloading etc. Said he couldn’t give me an exact time but would ring me in morning to advise exact ETA. I have never met a truck driver who was so organised. All of the above culminated in to me being blown away with Polymaster’s outstanding customer service. Thank you very much and please pass my feedback onto your Mgr Director. It was a pleasure to deal with a company who is so transparent and organised, congrats.

From entering details online and then talking with Tony Columbro to ensure I had details correct to then the text messages when the tank was ready. Then notified it was loaded and on its way to its new home. The whole process was professional and super smooth. Love the tank.

Once tank was ordered it was confirmed and outlets checked . Delivery day was advised and driver was excellent . Great company to deal with.

Good communication from Polymaster and delivered without a problem. Very happy with the quality of Polymaster products too.

Thanks to the driver, Bruce for delivery to a spot made difficult by recent rain. Managed to get tanks to their right spots. Good effort!

Sales people were excellent in providing updates to delivery and delivery driver also keep me informed of delivery times and helpful with information regarding the tank.

Great customer service especially Rachel. Also the driver was extremely helpful and professional in his handling of his job. Tank arrived on time as promised. The only little thing is that the tank was not put on position but close for us to push it the the foundation. Definitely we will order our next tank from them. Just recommended my friend to buy from Polymaster.

Good price. Great communication. On time friendly delivery service. Brilliant. Oh and the product is second to none.

Very happy with the product, also very happy with all the text messages telling me how the production was going. Will definitely be buying another tank from you in the future.

Besides the delivery arriving a day early the entire experience was excellent. Tim was excellent and did everything possible to help out to make sure the tanks were put in the best place. Thanks very much."

Ecstatic with delivery made by Mark Sinclair today - haven't had good old service like this in a very long time. Mark was polite, helpful & an absolute bloody gem. Highly recommend Polymaster to everyone.

Easy to deal with. Prompt delivery. Courteous and friendly delivery driver. Great experience."

My experience was excellent. I don't know how it could be better. Everything worked exactly as I hoped.

The customer service was fantastic with a step by step walk through on the setup of the tanks. The recommendations on how to get the best set up of the tank fittings pump positioning. To the delivery of the tanks and the positioning on the ground.

"From start to finish it was nothing but a great experience. Very professional. Great company with great staff."

Over the moon with the quality of the tanks and the service ????

Both truck drivers are excellent. Very helpful. All tanks are wonderful. Very quick delivery after placing order. Had phone calls from Polymaster to check tank details and progress of delivery.

"Great customer service from office, keeping me up to date with delivery time etc. Delivery man mark was on time, knowledgeable and did a fab job getting in a tight driveway. Very happy with my tank thank you."

First class service. First class product.

We’ve found working with Polymaster to be a positive experience. The quality of the products which we have used has been very high, and the willingness and technical capacity of the staff to tackle non-routine engineering modifications has given us confidence in the finished build.

The decision to sell Polymaster tanks to my customers is an easy one due to the fact that I strongly believe they are the best quality tanks on the market and I can confidently stand by the product I am supplying.

We are very pleased with the choice we made to go with Polymaster due to the quality and excellent service. We will endeavour to use more Polymaster tanks as we continue to upgrade our property.

Get in touch

Call Polymaster today on 1800 062 064

Recent Projects

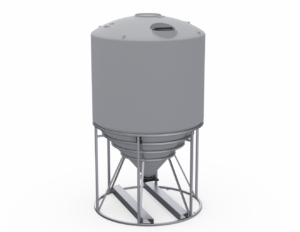

All our rainwater storage tanks are manufactured to the highest quality, hold product certification from an independent testing authority, and are certified.

Bird In Hand Winery

A water treatment company had a wastewater project for a winery in South Australia.

Read More

Maeil Dairies

Maeil Dairies has made its first investment into the Australian market through the construction of a nutritional powder...

Read More

Dungog Wastewater Treatment Plant

With any new build, there are complexities that need to be thought through. This particular design team had...

Read More

Terowie Mining Village Sewage Digestion Tank

These custom adjustments within the envelope of a standard 50,000 litre tank show the versatility of Polymaster tanks.

Read More

Northern Peninsula Area Regional Council

With a very specific client requirement, the Polymaster engineers had their work cut out.

Read More

Osborn’s Transport

With a fleet of trucks and buses on tight timetables and deadlines, it is important that refuelling times...

Read More