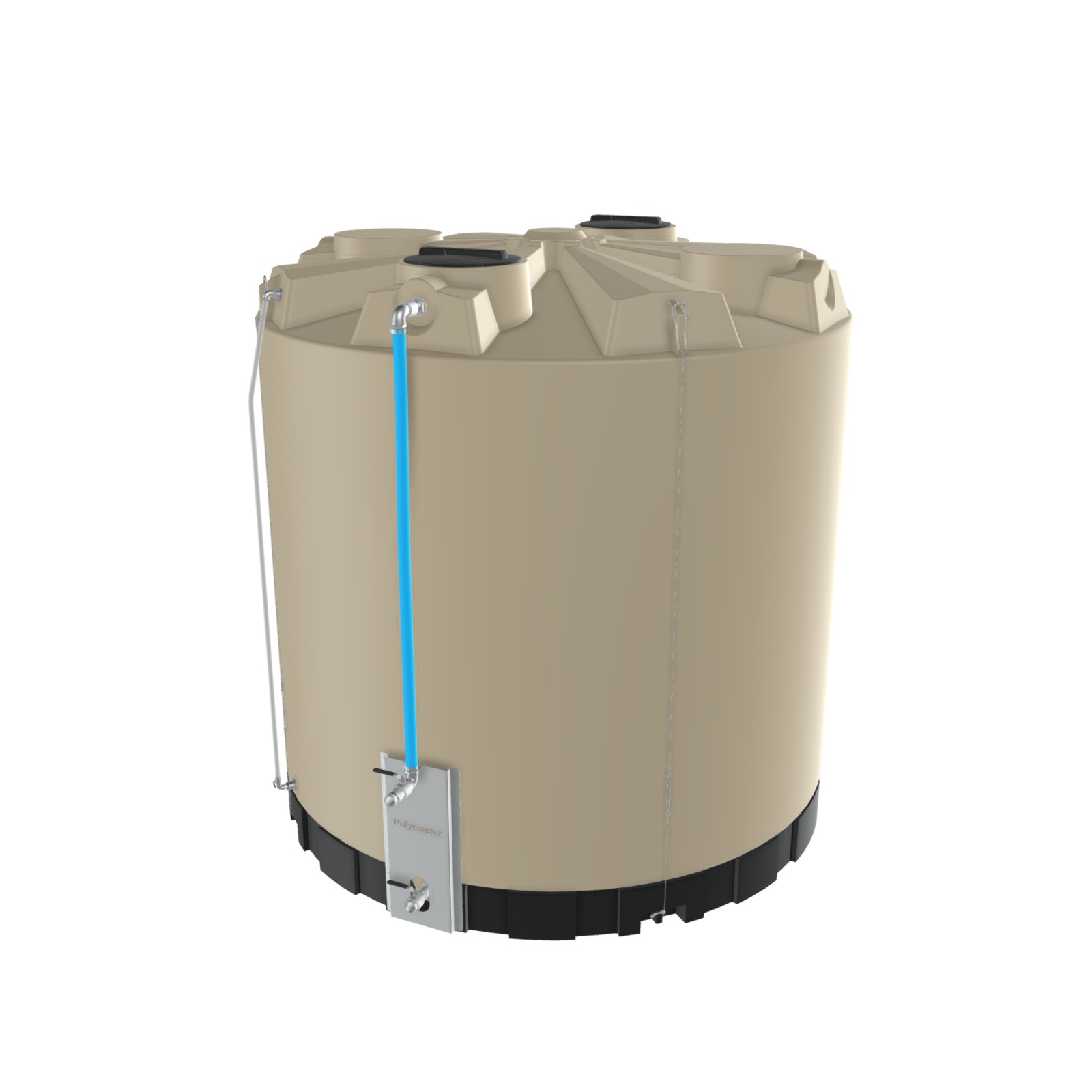

Sludge management is a cornerstone of water treatment, and at the Swan Hill Water Treatment Plant (WTP), it’s no exception. This water treatment facility along the Murray River provides clean drinking water to the region, but sludge from its clarifiers can pose a real challenge during peak periods such as summer if not managed effectively. Recently, Polymaster delivered three self-draining tanks to address a sludge overflow issue, ensuring operational efficiency and environmental compliance. Here’s how it works—and why our tanks were the right fit.

The Sludge Challenge at Swan Hill WTP

In water treatment, clarifiers separate solids from liquid, producing sludge—a thick mix of water, organic matter and sediments. For a plant supporting a community that relies on the Murray River as its water source, maintaining control over this byproduct is critical. During peak demand periods at the plant, additional buffer storage of sludge is required before being pumped offsite.

Polymaster’s Self-Draining Tanks: A Tailored Solution

To tackle this, Polymaster supplied three self-draining tanks, each designed to manage the specific demands of Swan Hill’s sludge control process. These tanks bring precision engineering to the table:

- Self-Draining Design: Featuring a sloped base and gravity-driven drainage, they eliminate sludge buildup without the need for pumps or constant manual intervention.

- Industrial-Grade Durability: Made from high-grade polyethylene, these tanks resist corrosion and wear from abrasive sludge, all while supporting a low-maintenance operation.

- Easy Installation: These tanks could be easily craned into position as one-piece with all the connection nozzles pre-fitted to the tank, for easy pipework connection onsite.

The Impact: Efficiency and Compliance

With the tanks installed, Swan Hill now has a robust system to contain and manage high sludge levels. The clarifier operates without interruption, and the risk of overflow is prevented keeping the plant aligned with environmental standards. For a region tied to the Murray’s health, that’s a significant win. Plus, the reduced maintenance burden helps the utility keep costs down.

Conclusion

At Swan Hill WTP, Polymaster’s Self-Draining Tanks are proving that smart storage solutions can turn a challenge into an asset. As water treatment demands grow, we’re committed to engineering answers that balance performance with sustainability. What sludge or liquid storage challenge are you facing? Let’s talk about how we can help.

Polymaster Chemical Storage & Dosing Projects

More Similar News

View all News

The Ultimate Cheat Sheet the Chemical Industry Should Be Using!

Why Cone Bottom Tanks are Perfect for your Business