Home Case Studies Terowie Mining Village Sewage Digestion Tank

Terowie Mining Village is set up to support the men and women that work across several mine sites in the Coppabella area of Queensland. The self contained village has a number of amenities including an excellent gym and pool, plus dining room, bar, offices and conference rooms. Located approximately 144 kilometres from Mackay on the Peak Downs Highway, the village is fairly self-sufficient.

Being beyond the reach of large infrastructure and mains water treatment plants, the community needs to process their waste on-site and independently.

The client uses an Activated Sludge Process at the village to treat sewage and wastewater. This process uses a “biological floc”, a living floating mass, made up of aerobic bacteria and micro-organisms that rely on constant aeration to ensure high oxygen levels and continuous movement of the sludge. The microbes feed on the sewage, neutralising any harmful bacteria such as E. Coli, eventually turning waste into an environmentally friendly fertiliser.

The Polymaster team began with a robust 50,000 litre tank, structurally rated to support liquids with a specific gravity of up to 1.5.

Housing the micro-organisms was one thing but creating an environment they could thrive in was the key with this project. The quantity of air fed into the tank improves the speed and quality of processing the waste. Given the optimum environment, the bacteria are able to grow and multiply efficiently, which in turn means the volume of waste that can be processed is greatly increased.

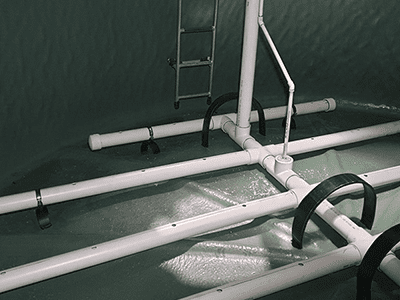

With this in mind, internal pipework was welded to the base in a rib-like manifold to create the aeration diffusers, which are used to oxygenate the wastewater and sludge.

At the top of the tank, a large open vent allows gases produced in the digestion process to escape and reduce pressure on the structure. Manhole ports in the roof allow for safe inspections into the unit with screw on lids for safety.

These custom adjustments within the envelope of a standard 50,000 litre tank show the versatility of Polymaster tanks and the ability of the Polymaster Engineered Solutions team to build a fit for purpose solution for our customers.