Or, what’s the difference between a Rainwater tank and a Polymaster Chemical-grade tank?

These two questions (and similar) come across our desk regularly, which we hope to answer in this article.

The short answer to the question is – a rainwater tank will most likely fail and may result in a catastrophic spill on-site.

To safely contain liquid chemicals in Polyethylene, a rotationally moulded tank must take into consideration the material (type of PE) and the construction of the tank (actual manufacturing process).

Why can’t you store sodium hypochlorite in a rainwater tank? Let’s break down the 4 primary differences between a typical rainwater tank and our chemical-grade storage tanks.

- Type of Polyethylene

- Chemical Compatibility

- FEA Modelling (Finite Element Analysis)

- Construction

1. What are the different types of polyethylene?

Not all polyethylene is created equal … and nor should it be.

In the rotational moulding process of rainwater tanks, standard hexene-derived LLDPE (Linear Low-Density Polyethylene) is used to create the water storage vessels.

As a baseline LLDPE has good chemical resistant properties, however not all chemicals are the same.

Depending on formulation and concentration, some chemicals can and will degrade standard LLDPE.

Chemicals such as Sodium Hypochlorite, 98% Sulphuric Acid, Magnesium Sulphate, Nitric Acid, Ammonium Chloride (and many more), are categorised as ‘aggressive’.

These chemicals, especially at high concentrations, tear apart polymer due to oxidation. Once oxidation has commenced, then cracks will propagate from ‘crazing’ (fine cracks) and an eventual failure will take place.

To stop the effects of oxidation, the polymer needs to be formulated with a unique blend of antioxidant and UV additives. These additives allow for a superior antioxidant and UV strength to that of a normal polymer. Without these additives, the likelihood of a tank lasting the test of time is greatly diminished.

Polymaster blends its own PE which includes these antioxidants (& a few other proprietary formulations). We have three materials to choose from depending on the type of chemical being stored and the size of the tank.

- Standard LLDPE (our blend reference is 7032)

- Chemical-grade LLDPE (our blend reference is 7080) suitable for up to 10,000ltr tanks, for ‘aggressive chemicals’ such as Sodium Hypochlorite and Nitric acid.

- Rotationally-moulded HDPE (our reference blend is 7088) suitable for tanks 10,000ltr upwards, and for ‘aggressive chemicals’.

- By understanding the type of chemicals being stored the right tank can be selected and ‘fit-for-purpose’. That’s why a Polymaster chemical tank comes with a 25yr UV design life.

2. What is Chemical Compatibility?

If you are being ‘sold’ a PE tank without being asked what chemical is stored inside, then you need to re-assess your buying process.

As a safety measure, simply refer to the above comment, “not all chemicals are the same”.

Similar to Polymaster’s Chemical Compatibility Chart, (readily available on polymaster.com.au) all high-quality tank manufacturers should be able to offer you documentation or published guide on which chemicals work best with which type of PE for rotational moulding applications.

As some chemicals can be proprietary to a manufacturer, its name may not be easily recognised. An SDS (Safety Data Sheet) is required to validate the correct polymer for the tanks’ construction. Our in-house polymer chemist will match up the SDS properties with our PE material.

WARNING

Understanding the proposed stored chemical is also important in selecting the correct ‘seals’ used on fittings/nozzles on the tank so that they do not deteriorate.

Additionally, a tank manufacturer must know if the chemical fumes or not in order to add the proper precautions, such as a sealed tank and/or a fume scrubber, into the solution.

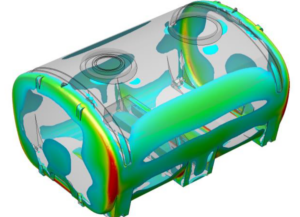

3. What is FEA Modelling (Finite Element Analysis)

Every substance has its own Specific Gravity (SG), or relative density assigned to it. Specific Gravity is the ratio of density of a substance to the density of a given reference material. Water has an SG of 1 at its densest and is the baseline in which nearly all liquids are measured against.

As all chemicals have their own SG, a suitable tank is required to contain the liquid, therefore the strength of tank needs to match the chemical’s SG.

A rotationally moulded tank needs to be designed to accommodate the hydrostatic pressure (force) being exerted on the tank walls. The higher the chemical’s SG, the thicker the walls, roof and floor of a tank need to be.

FEA is undertaken for all tanks in the Polymaster range for their respective SG rating. FEA modelling in rotational moulding is a structural analysis of the impact of what pressure, different SG liquids place on the structure of the tank.

Volume, height, and the SG of the liquid are all factors which influence the design of the tank.

The benefit of an FEA Modelled tank is that wall thickness can be optimised where it needs to be, i.e. where the outward pressure is highest.

This ensures the chemical, and its SG is matched to the most appropriate wall thickness, therefore ‘fit-for-purpose’ for strength and when matched to the correct PE material, it will last the test of time.

Each tank is ultrasonically thickness tested on up to 24 specific places on a tank to confirm the thickness exceeds the nominated FEA model measurements. Every tank must pass this testing phase to be accepted as a certified AS4766 tank.

Construction and testing of a purpose designed and built chemical tank is next level roto-moulding compared to the manufacture of a rainwater tank.

4. How are Chemical storage tanks made?

Before we round out this article, let’s agree on the following point –

No one wants a tank failure in the field!

A failed chemical tank can have a more devasting effect on the surroundings/environment than a tank only holding water.

With this understanding, the manufacture of a chemical tank must have significantly more rigour around it, when it comes to construction.

A Chemical tank at Polymaster is manufactured in a purpose-built, stand-alone facility that is physically separate from the rainwater tank plant.

The poly welding processes used, the QA and testing procedures and the skill set of the personnel in the chemical facility are all very different from those at the other plant.

Here are some examples of Polymaster measures:

- Manufacturer drawings are signed off by the customer before build commences.

- Certified poly welders for all factory-installed fittings.

- Minimum 6hour hydro test to ensure no leaks around any welds. A 24hr standing pipe test to assimilate the SG of the proposed chemical can also be undertaken.

- 24pt ultrasonic thickness testing and impact drop test.

- All welded flanges greater than 140PE (size/diameter) can only go on a 1.5SG tank or greater.

- All welded flanges greater than 110PE must be supported by a Polymaster stiffening cone (not gussets), to provide greater strength to the heavier fittings.

- Comprehensive I&TP (Inspection and Test Plan) is recorded for each build and recorded against each order.

The attention to detail the chemical factory crew adopts when building each project is a reflection of their pride in their workmanship and the confidence that each tank will safely and securely contain the liquid it has been designed for.

Additional Resources Available.

If you are in the market for a chemical tank and need more information, we have available a whole suite of resources online, including

- GA/PDF drawings for all tanks

- Step files to easily incorporate into your CAD files

- Datasheets on each tank, including different SG and Chemical Grade material

Our chemical team are happy to help you navigate through your requirements. Simply call 1300 062 064.

More Similar News

View all News

IBC Totes in Chemical Industries: Caged vs. Cageless Options

Why a Self-bunded tank outperforms a Single-Walled Tank!