PRODUCTS USED IN THIS PROJECT

Modified Forecourt Station containing 3 x 10,000L Chemical Tanks

CLIENT BACKGROUND

Wilmar AgServices (part of the Wilmar Group) operates a liquid fertiliser and stock-feed business based near the Wilmar Bioethanol plant at Sarina Queensland.

The business is known in the sugar cane, horticulture and agri business industries as an award winning and innovative producer of efficient and environmentally friendly nutrient solutions. This is especially crucial as a number of their customers are within sensitive Great Barrier Reef Catchment areas.

PROJECT REQUIREMENT

Wilmar AgServices produce a natural protein supplement for cattle, using co-product from their bioethanol fermentation process. This fermented product is called Suplaflo 10NP, a flowable supplement containing natural protein, with inherent nutritional value and a capability to carry other important nutrients. Wilmar’s Suplaflo 10NP is a range of liquid supplements for cattle.

Wilmar AgServices needed to be able to add a precise dosage of phosphorus at their Oonooie Plant to deliver a whole new product range enriched with phosphorus.

Phosphorus requires precise dosing and at relatively small amounts needed per tonne, an accurate metering and chemical storage system was necessary.

Wilmar AgServices approached Polymaster to provide a solution to store the phosphoric acid (30kL) and to also dose into the Suplaflo 10NP production line at their facility.

The physical footprint on-site was a major consideration when proposing a solution.

SOLUTION PROVIDED

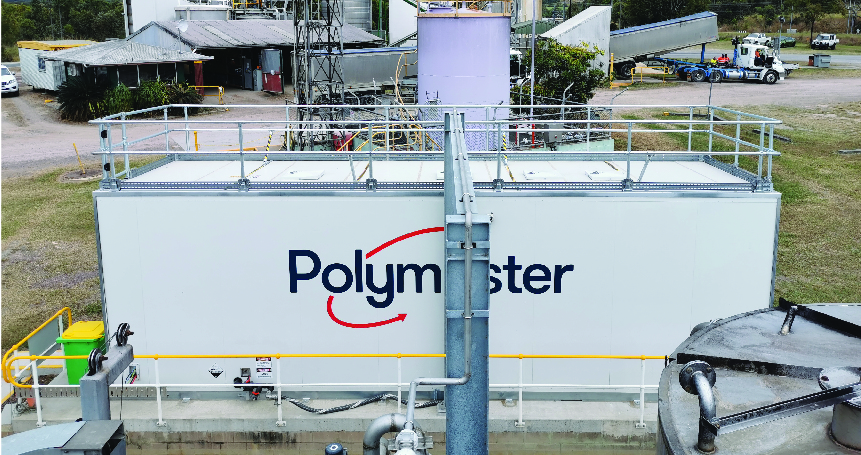

After consultation, the Polymaster Engineers were able to guide Wilmar AgServices to a 30kL rectangular forecourt-style unit (as shown), instead of a round tank.

The forecourt-style unit ticked the functional box as it could fit into the designated area comfortably and at the same time provide protection from the elements for the equipment contained within its built-in control room.

The final design was constructed on a Duragal hot-dipped galvanised base frame, with a CAT 2 wind loading (Region C) frame which was wrapped in 100mm insulated wall and roof panelling. This unit was built to withstand wind gusts up to 50m/s (cyclonic).

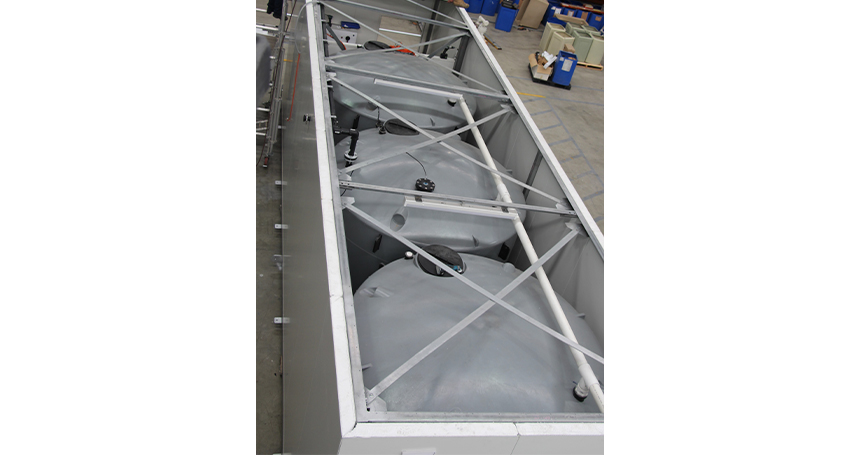

The unit perfectly housed 3 x 10kL interlinked doubled-walled tanks. Within the control room, 2 x 3 Phase diaphragm pumps (filling and dosing), and a Polymaster power control panel with variable speed drives, tank level monitors, instrumentation and programmed safety switches were installed.

Additionally, Wilmar AgServices required roof access and a full safety handrail system with ladder – all constructed to meet AS1657-2018.

Logistics were top of mind from the onset as this project required road transport of 2,019kms to Sarina (QLD) without the need for pilot vehicles – a freight saving.

The result – was a truly fit for purpose, easily maintainable unit with safe access points to the inner tanks which incorporated appropriate ventilation within all confined spaces.

As with most Polymaster products, this unit has been designed to be a ‘plug and play’ solution to minimise onsite installation costs.

SCOPE OF WORK

- Product Design

- Engineering

- Product Manufacture

- Delivery

CHECK OUT THE VIDEO HERE

More Similar Project

View all Projects

Bird In Hand Winery

Brookeshill Orchards