When storing one or more of the 1900+ chemicals in the market, you really need to be confident your tank can cope with the aggressive nature of some chemicals.

At Polymaster, the development of polymer suitability starts in the laboratory and filters into our mixing, extruding, grinding processes through to material analysis, PIAT (Peak Internal Air Temperature) and AS4766:2006 certification.

Polyethylene is classified by;

- Density (PE property which measures mass per unit volume and tested to ASTM D1505)

- Melt Flow Index (viscosity/molecular weight)

Some of the most common polyethylene are:

- High Density (HDPE)

- Low Density (LDPE)

- Linear Low-Density PE (LLDPE)

- Cross-Linked PE (XLPE)

Linear Low-Density Polyethylene (LLDPE) is the polyethylene commonly used in rotational moulding.

LLDPE is a co-polymer of ethylene and another longer olefin such as Butene, Hexene, and Octene. Through the use of these co-monomers comes about the changes in a polymer structure that create side groups on the main chain of polymers that act like branches resulting in improved physical and mechanical properties.

Understanding how these properties perform allows a skilled tank manufacturer to have absolute confidence, your chemical will be securely stored.

Polymaster’s technical experience, commitment to quality and world-class R&D facility allows us the opportunity to produce customer-driven innovations so that we can set the benchmark in the roto-moulding industry.

We offer a comprehensive range of high-performance engineered polyethylene along with world-class technical support to satisfy the most demanding storage requirement. We produce a broad range of polymer grades appropriate for manufacturing the most critical storage solutions.

Our proprietary range of Hexathene™ polyethylene leads the industry in providing high-performance properties for a variety of applications. Unique formulated additives are blended for increased resistance to aggressive agents which tend to diffuse through polymers causing oxidative degradation. We stop this with Hexathene™.

WHAT DO THESE ENHANCED HEXATHENE™ POLYETHYLENE GRADES OFFER?

- Excellent creep properties

- Increased stiffness

- Increased mechanical properties for elevated temperatures

- Improved ESCR (Environmental Stress-Cracking Resistance) properties

- Enhanced resistance to aggressive chemicals

- Improved thermal properties for long term end use

- Excellent impact

- Antimicrobial Properties

- Flame Retardancy

- Metal Detection Properties

INNOVATIVE PRODUCTS DESIGNED TO PUSH BOUNDARIES

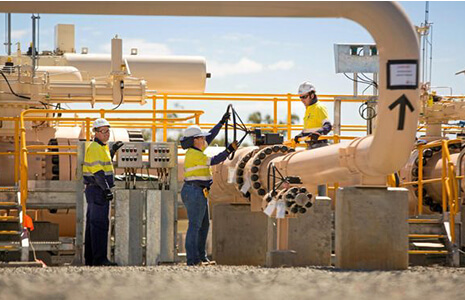

As an industry leader with extensive technical experience and a commitment to quality and service. We are relentless in creating new and innovative products by testing boundaries, evaluating outcomes and providing the ideal storage solution.

We like to think we deliver more than applications and solutions. We deliver a promise that you can rely upon us to store, secure and safeguard your project.

To view our range of chemical storage containers here or Call us today on 1300 062 064 to assist you with your chemical storage requirements.

More Similar News

View all News

Why Cone Bottom Tanks are Perfect for your Business

The Role of Groundwater in Gas Extraction: Processes, Challenges and Storage Solutions